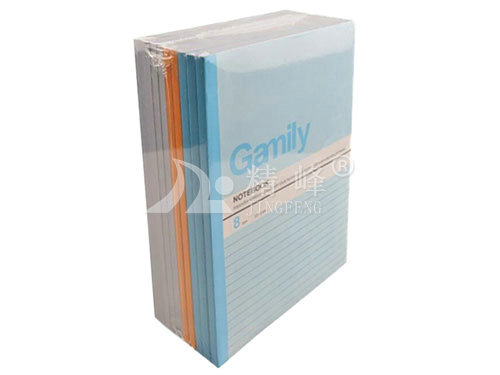

茶叶盒热收缩包装样品

2022-04-07 14:57:30 来源:本站

适用范围 Scope of application

食品、药品、饮料成组包装、碗面、奶茶、蚊香、墙纸、练习本、滤清器、电气开关、保鲜膜、垃圾袋、各种文具、工业零件和日用化妆品贴体包装等。

Use for packaging of food, medicine,beverage, bowl noodles, milk tea, mosquito repellent incense, wallpaper, exercise books, filters, electrical switches, preservative films, garbage bags, various stationery, industrial parts and body fitted daily cosmetics, etc.

特别推荐 Special recommendation

■ 本机采用的是日本技术,全部使用进口电器元件,是在日本技术和丰富的经验中诞生的高速自动包装机。

Jf-590full servo high speed heat shrinkable packaging machine is a new product independently developed by our company. The machine adopted high quality imported electrical components, PLC and man-machine interface operation, so that the equipment operation process is more stable and convenient.

■ 本机操作简单,质量可靠,性能稳定。变频调数,无级变速。整机的控制集中由PLC完成,减少了故障点。热收缩炉高效双温区,无极调速,自动控温。高效热风循环,保证收缩质量。

The machine has the advantages of simple operation, reliable quality and stable performance. Variable frequency regulation, stepless speed change. The control of the whole machine is centralized by PLC, which reduces the fault points. High efficiency double temperature zone of heat shrinkable furnace, stepless speed regulation and automatic temperature control. Efficient hot air circulation to ensure shrinkage quality

性能特点 Performance characteristics

■ 彩色触摸屏控制系统,采用三个伺服电机驱动,整机操作方便,稳定性高,包装效率高,故障率低;袋长,速度与温度均可单独调整,操作方便,准确。

Touch screen control system, driven by three servo motors, the whole machine has the advantages of convenient operation, high stability, high packaging efficiency and low failure rate; Bag length, speed and temperature can be adjusted separately, which is convenient and accurate.

■ 防切安全离合装置,不损坏包装物。

Anti cutting safety clutch device, without damaging the package.

■ 高感度光电眼色标跟踪,数学化输入封切位置,使封切位置更加准确。

High sensitivity photoelectric eye color mark tracking and mathematically input the sealing and cutting position to make the sealing and cutting position more accurate.

■ 温度独立PID控制,更好适合各种包膜材质。

Temperature independent PID control, better suitable for all kinds of materials.

■ 定位停机功能,不粘刀,不浪费包膜。

Positioning stop function, no sticking knife, no waste of material.

■ 传动系统简洁,工作更可靠,维护保养更方便。

The transmission system is simple, the work is more reliable and the maintenance is more convenient.

■ 切到产品自动反转,重启后直接开机方便操作。

Automatic reverse of the cutter when it cut the product and start it directly after restart for convenient operation.

■ 增加废料回收装置,使包装更美观,比传统的对折膜包装机节省材料约20%-30%。

The waste recycling device to make the packaging more beautiful, saving about 20% - 30% of materials than the traditional folding film packaging machine

■ 可配备打码机或喷码机,无需使用人工。

It can be equipped with printer or inkjet printer without manual operation.

■ 具有电机刹车控制,设备反应灵敏。

With motor brake control, the equipment is sensitive

■ 热收缩炉高效双温区,高效热风循环,自动温控,保证收缩质量。

High efficiency double temperature zone, high efficiency hot air circulation, automatic temperature control to ensure shrinkage quality

主要技术参数:

| 最大膜宽 Maximum width of film | ≤590mm | ||||

| 型号 Model | 120 | 150 | 180 | 210 | |

|

包装尺寸 Packing size |

L :袋长 |

L:60 - 320(mm) |

L:100 - 450(mm) |

L:150 - 530(mm) |

L:180 - 600(mm) |

|

W:物宽 |

w:10 - 200(mm) |

w:10 - 200(mm) |

w:10 - 200(mm) |

w:10 - 200(mm) | |

|

H:物高 |

H:5 - 35(mm) |

H:35 - 70(mm) |

H:75 - 100(mm) |

H:80 - 130(mm) | |

|

包装速度Speed |

30 - 150(包bag / 分min) |

30 - 150(包bag / 分min) |

30 - 135(包bag / 分min) |

30 - 100(包bag / 分min) | |

|

薄膜种类 Material of film |

PVC;POF等热收缩膜 / PVC, POF and other shrinkable film | ||||

|

额定功率 Total power |

包装机 Packing machine:4.5KW;收缩炉 Drying oven:15.5KW | ||||

|

电源 Power S ource |

主机 Packing machine:220V,50HZ/60HZ;收缩机Drying:380V,50HZ/60HZ | ||||

|

主机尺寸 Packing machine size |

5000 * 1170 * 1500 mm | ||||

|

收缩机Drying oven size |

2600 * 600 * 1700 mm | ||||

|

整机重量Machine weight |

主机 Packing machine:1000KG | 收缩机 drying oven:600KG | |||